Contact Us: 020-31125660 Fax: 020-23889671

Wecome to Guangdong Eacoon Energy Technology Stock Co.,Ltd. website

SOLUTIONS |

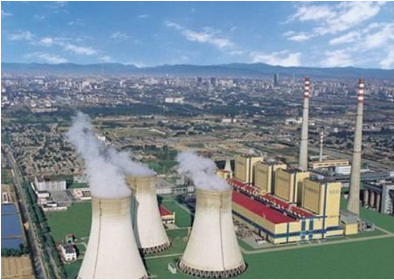

Thermal Energy Reform of Environmental Protection

China is a big energy-consuming country. With the continuous development of China's economy, the shortage of energy supply, especially the shortage of oil resources, is even more prominent. By the end of 2005, there were 1,349 enterprises in China's boiler manufacturing licenses, including 639 C or above, with an annual production capacity of 180,000 tons. The 70 companies of the Industrial Boiler Industry Association produced a total of 63.02 million tons of steam (10,863 units) in 2005. According to statistics in 2005, nearly 600,000 industrial boilers and 1.65 million tons of steam are used in the country, which is close to twice the installed capacity of power station boilers. About 480,000 of the boilers are coal-fired industrial boilers. The actual operating efficiency of industrial boilers is only about 65%, which is 15-20% lower than the foreign advanced level. China's industrial boilers are large in scale, small in average capacity, and mainly based on coal burning. The annual consumption of fuel is about 400 million tons of standard coal, accounting for about a quarter of China's total coal output. Due to the low efficiency of boiler operation, industrial boilers emit a large amount of soot and SO2 and NOX pollutants, which has become one of the major soot pollution sources in China. China's annual industrial boiler pollution, energy waste is quite serious, burning more than 60 million tons of coal per year, the energy saving potential is huge. Other emissions are: smoke emissions: 2.8 million t / a; SO2: 9 million t / a; CO2: 1.25 billion t / a. Based on economic conditions and resource constraints, the transformation of China's boilers cannot simply pursue the advanced nature of technology. It is necessary to comprehensively consider the technical, economic and environmental needs of industrial boilers and seek an industrial boiler development path suitable for China's national conditions. The establishment of systematic industrial boiler technology, economic and environmental evaluation methods is conducive to the improvement of the overall technical level of industrial boilers and environmental improvement. In order to solve the problem of low efficiency of enterprise boilers, we have proposed a comprehensive energy-saving overall solution through the thermal energy supply efficiency of the overall diagnostic thermal enterprise, from boiler body efficiency to boiler operation efficiency, steam transportation efficiency, steam use efficiency, waste heat recovery. , condensate recovery, fuel delivery system, fuel supply mode, fuel form and other comprehensive comprehensive thermal efficiency, overall design, overall transformation, to achieve the most efficient operation of thermal energy operation system. Aiming at reducing the energy cost of users, we will achieve a comprehensive and fundamental energy-saving goal. |